'Technological torture': how Apple tests its devices in its secret laboratory

Counterpoint visited the laboratory where Apple subjects its devices to drops, water, heat, and extreme vibrations

Apple devices undergo environmental and mechanical tests before reaching the market. The goal is to ensure their resistance and durability anywhere in the world.

Counterpoint Research took part in an exclusive tour of this laboratory, where tests simulating humidity, heat, dust, and drops are performed on the iPhone.

Extreme climate and environmental resistance tests

In one of the rooms, conditions like those of the Arizona desert are recreated to assess how dust affects the charging port or the speakers.

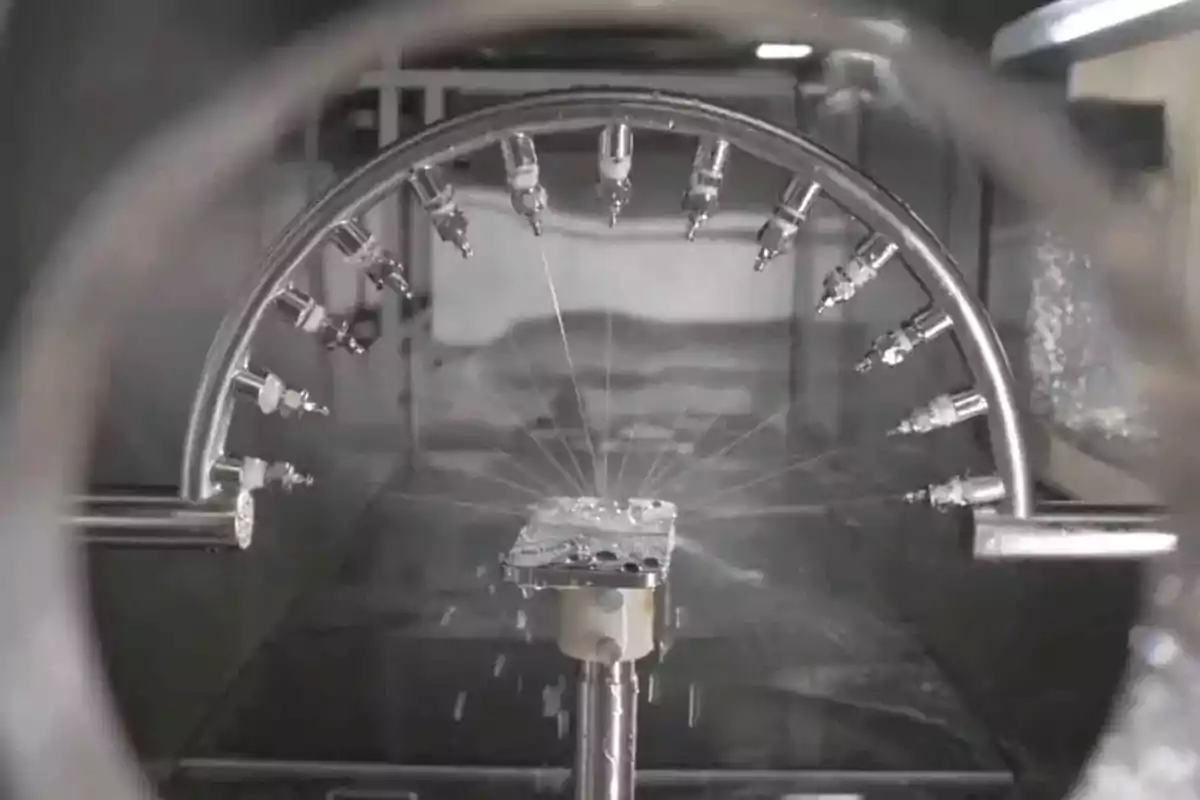

Intense rain and salty environments are also simulated for more than 100 consecutive hours. These tests are key to obtaining certifications such as IPX5 or IPX6.

Immersion, pressure, and everyday liquids

The products are exposed to high-pressure water jets and submerged in tanks that simulate depths of up to 6 meters (19.7 feet), reaching levels such as IPX7 and IPX8.

They are even tested with perfumes, juices, sodas, and sunscreen to mimic real-life usage situations.

Accidental drops

According to Counterpoint data, drops are one of the three most common reasons for device repairs.

Apple simulates these types of accidents with robots that drop the devices from different angles onto surfaces such as asphalt and granite.

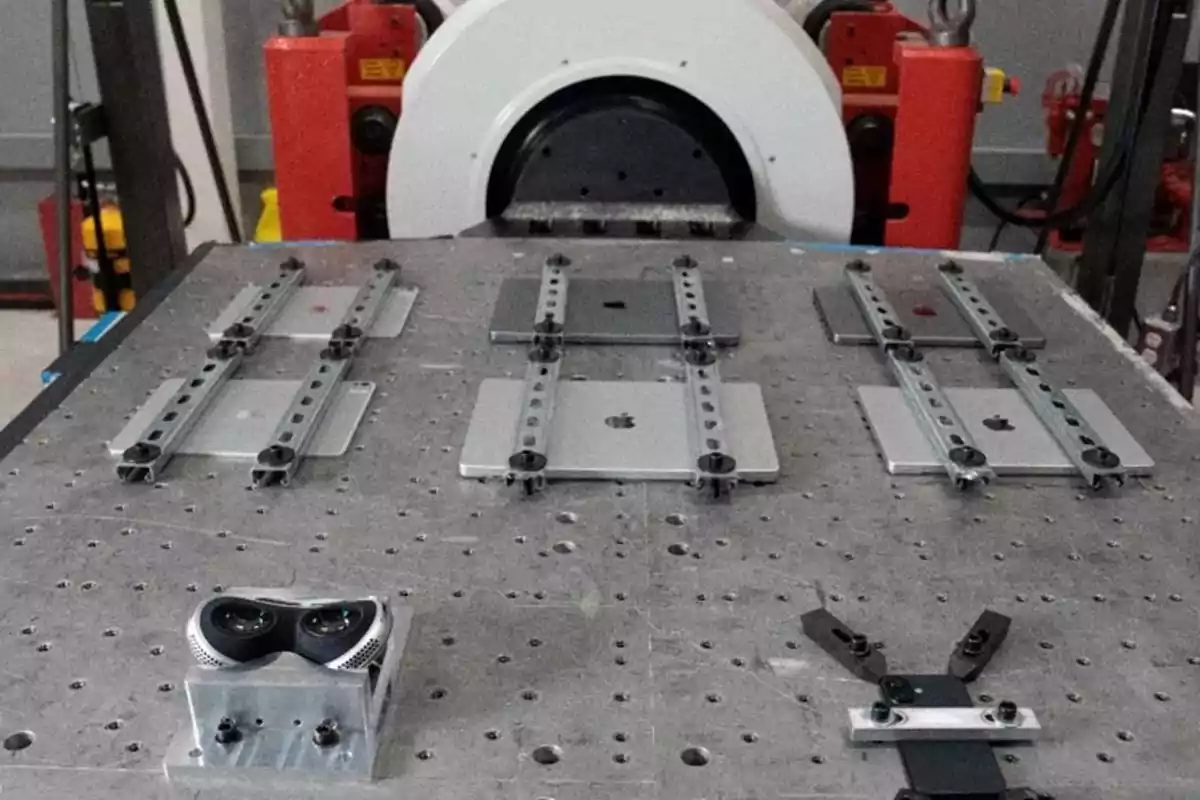

Vibration and transport

Once the impact tests are passed, the devices undergo vibration tests that mimic daily transportation.

They are fixed onto metal plates and subjected to different intensities to verify that they don't suffer damage while in motion.

Durability vs. repairability

One of the points highlighted by Counterpoint is that, although Apple products are durable, that doesn't mean they are easy to repair.

The firm also appreciated the obsession with detail that Apple demonstrates in each of its tests.

More posts: